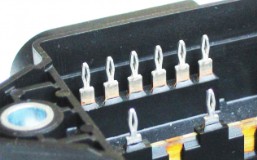

BIDDS connector contact

The BIDDS press-in contact is a direct connector for printed circuit boards.

Principle and process are the same as for the tested and approved BIZON press-fit contact.

Only the spring length is longer so that the deformation remains in the elastic range, as with a plug-in connector.

The plated-through hole of the printed circuit board serves as the plug-in socket, in the same way as for press-fit technology. Only the insertion force is smaller.

The mating cycles (repairability) are much higher than with press-fit technology, and the same contact or connector can be reused. This is not permitted with press-fit technology.

This not only saves the expensive female connector and an electrical connection point as a source of error.

Safety in the current path is also doubled by omitting a connection point.

The high current strength must be clarified in each individual case, since the contact area in the hole may be reduced.

The mating force can also be specified individually for each project with individual contacts.

In this way, the contact can also be designed as a safe assembly plug-in connection with increased holding forces.

The aim remains a gas-tight and thus corrosion-resistant connection. Only the internal mechanical holding force is reduced and must be ensured by external measures (screwing, clamping, etc.).

Simple alternative to "SKEDD".

Or

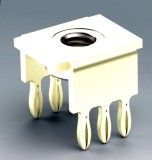

As a free connector with a simple tube (drilled or rolled) as socket part.

Best contact and vibration characteristics. The resilient part is enclosed by stable tube.

The contact forces act in a closed metallic system from the inside to the outside.

No support via plastic.

This has many advantages.

- Spring-loaded pin in stamping technology

- Higher contact reliability and current carrying capacity than conventional connectors with tulip springs

- as typically four defined contact surfaces per contact.

- Due to the design, all four contact surfaces are in contact with the socket wall with the same force.

- The electrical separation point is remote from the contact point. A disconnecting arc does not destroy it.

- High vibration resistance

- Socket and pin are easy to manufacture with the same conductor cross-sections. This saves material and space.

Would that be of interest to you? Telephone: +49 7026 3004

Or send me here a few lines.