High temperature, relaxation

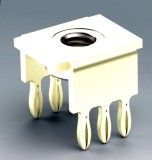

Press-fit connections in the high temperature range? Relaxation?

At high currents and temperatures above 120 °C the new highly conductive copper alloys are ideal.

Great importance is often attached to the metals' resistance to relaxation (reduction of elastic stress).

In contrast to connector contacts, the relaxation of press-fit contacts in printed circuit boards is not very important.

The printed circuit board relaxes first and more under the pressure of the contact, and the tension in the contact is reduced. No tension - no further relaxation.

Example:

CuSn6 still has 80 % residual stress after 100 hours at 150 °C.

An ordinary FR4 PCB has a glass point Tg of 135 °C. This means that at this temperature the resin is already soft and gives way to contact pressure. The elastic stress between contact and hole is reduced by the resin matrix flowing away. The contact feels only a strongly reduced counterforce.

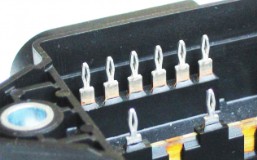

A press-fit contact with sufficient elasticity reserves like the BIZON-contact can make positive use of this relaxation of the circuit board.

The contact area and holding force are demonstrably increased.

Advantage: When selecting the contact material for higher temperatures, the (expensive) relaxation resistance can therefore be underweighted.

The FR4 PCB is usually the bottleneck when it comes to current and temperature.

This is of course not the case when pressing into metal (bus bars, stamped grids) or into ceramic and glass PCBs.

Sensors? Very high temperatures?

BIZON contacts could also be made of stainless steel!

Then 400 °C are also possible.

With small currents, the higher material resistance is not important.

And stainless steel can be gold-plated directly at low cost.

If this is a topic, please call me: 07026 3004

Or click here.