Safety

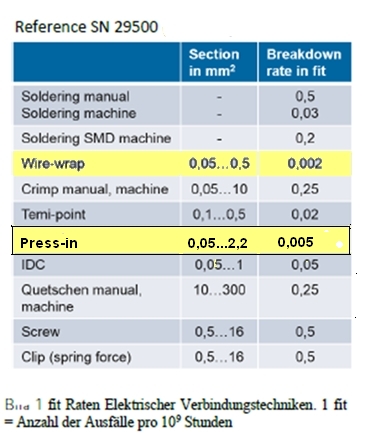

The WIZON contact combines the safest known electrical connection techniques.

Press-fit technology and winding technology.

The wire wrap technology, which was already frequently used in space travel 40 years ago, achieved the lowest failure rate of all solderless connection techniques.

The prerequisite was stripped wires.

The WIZON contact further improves this error rate and the range of applications, because the wire is not simply wound around a square pin, but the square pin is pressed into the wire winding. Much higher contact forces act there. So even insulated wires can be contacted, because the enamel has a lower strength than the copper. As a result, the enamel is always displaced and a gas-tight connection is made between the contact and the copper wire.Unlike almost all connection techniques, the WIZON connection is self-aligning. According to the underlying physical principle. This allows different wire diameters to be wound on the same contact over a wide range. No auxiliary tools and control measurements ( like crimping) are required.