WIZON-contact

The brand new WIZON contact

The safest wire connection that comes ready from the winding machine

Wire diameter 0.04 to >2.0 mm

No stripping - no crimping - no soldering - no welding - safe.

only press fit printed circuit board

Suitable for high current

Connection is made immediately by the winding machine.

Very simple and safe.

All electromagnetic components such as motors, coils, relays, transformers, etc., can be securely connected to PCBs, pins, flat connectors or busbars in a purely mechanical way using this technology.

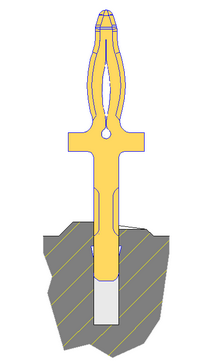

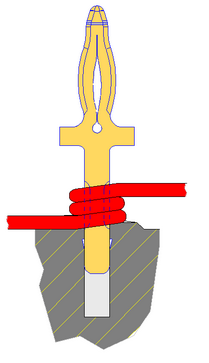

Application of the WIZON contact

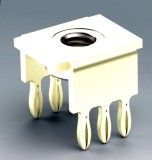

Insertion hole in plastic body

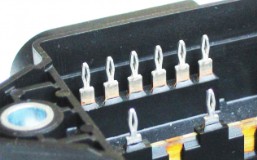

WIZON contact fixed

before winding

enamelled wire wound

around the winding area.

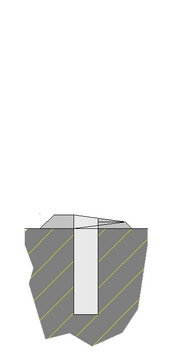

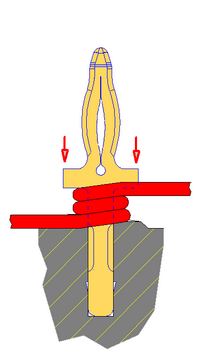

Push in on end position

The contact is moved

Press-in of the PCB

- done -

Best direct and gastight contacting from wire to PCB

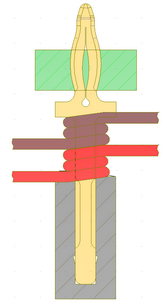

Multiple winding

Several windings (also with different wires) can be applied. The contact length increases accordingly.

Or you can use the practical motor terminals.