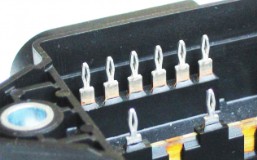

Corrosion, bare contacts

Corrosion at uncoated, bare contacts

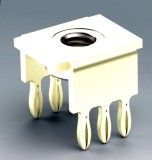

Very often, connector contacts have press-fit zones as a connection to the printed circuit board.

Refined or protected surfaces are required in the connector area. Tin plating, silver plating or gold plating, each with a sub-nickel coating, are common.

Thicker layers are required due to wear caused by multiple mating operations (mating frequency).

However, a press-fit connection acts physically quite differently from a plug-in connection. Thicker tin layers are scraped off and free tin chips can form. Precious metals do not bring any advantages and are too precious for this.

Therefore, two different selective galvanizations are always required for such contacts. This is also expensive.

Silver-plated contacts are treated with thiol as tarnish protection. This always wets the entire contact, including the blank areas.

This passivation therefore also protects the blank press-fit zone. Since thiol has a lower hardness than copper, it is also displaced during press-fitting. The electrical connection does not degrade as a result.

BIZON contacts can usually be used blank, i.e. uncoated, or with bare stamped edges in the case of pre-coated band material. This saves a complete galvanizing process.

BIZON press-fit connections have gas-tight contact areas. Connectors do not have gas-tight contact areas. This means that the contact area of a good press-fit connection can no longer be attacked by corrosion. Therefore, it makes no physical difference whether the contact radii of a BIZON contact are coated or uncoated.

Manufacturing from pre-coated strip material is often advantageous, but results in bare stamped edges. The edge radii of the BIZON contacts are also uncoated.

As a rule, there is therefore no reason to forego the cost advantages of a bare BIZON press-fit zone.

An exception would be, for example, stress corrosion cracking of brass in an environment with a high ammonia content. In this case, closed tinning is recommended.