Examples

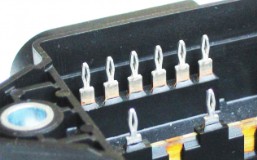

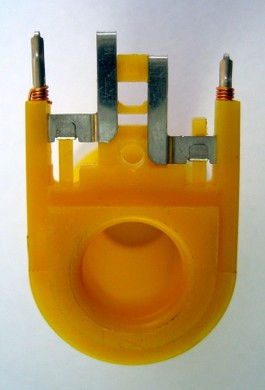

Motor terminals

Instead of insulation displacement connections

WIZON motor terminals can be used.

These terminals are inserted into a pocket similar to an insulation displacement contact before winding, or are molded in immediately with the insulator.

The electrical connection with the wire is done by the winding machine.

The part comes ready connected from the machine.

Each wire has its own terminal. This means that any circuit can be realized in the smallest possible installation space without additional connection elements.

If a different winding level is required, separate terminals can be bent off.

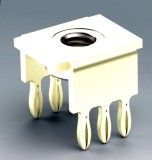

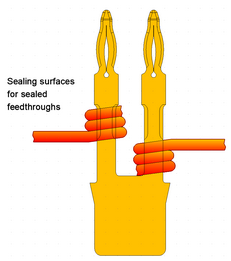

Sealed feedthroughs

Motors for pumps often have to be sealed off from the electronics.

This requires electrical feedthroughs that are sealed with potting compound.

WIZON motor terminals can have sealing areas for this purpose.

Example

solenoid

winding position end position

The principle of the WIZON contact can be implemented on many contact designs.

example

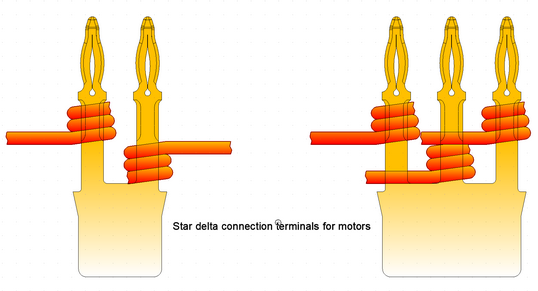

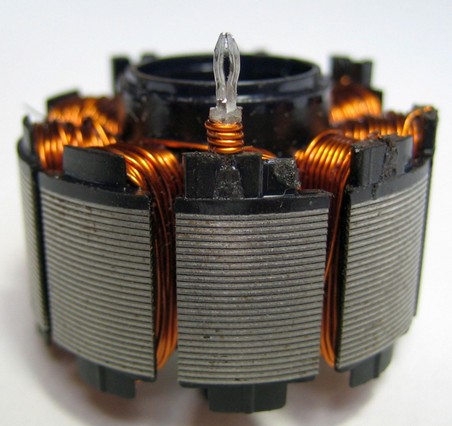

motor

For motors, the wire can be routed to the next pole without interruption. Thus, only 3 connections are required.

The beginning and end of the total winding are wound onto a WIZON contact.

Instead of 6, only 3 contacts are required. This also results in a large saving of space on the PCB. No unnecessary high current path on the PCB.

So that three identical contacts can be used, there are several possibilities:

1. the first terminal is wound with half the number of wraps, the two intermediate taps are wound with twice the number of wraps, and the end of the winding is wound with half the number of wraps on the first terminal.

2. all terminals are wound with the same number of turns, but the plastic support for the wire on the first contact is lowered by the height of the wraps so that there is room for the second wrap. Similarly, the plastic support for the intermediate terminals is raised.