Technology base

The proven technological basis of the WIZON contact

The WIZON contact principle is based on a connection technology according to IEC 60352-1 which has been proven for decades and is suitable for space applications.

The consequent development and inversion of the principle made it possible to contact enamel wires safely as well as increase the connection reliability.

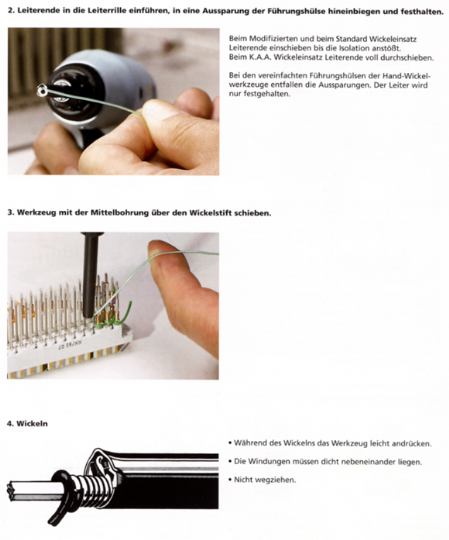

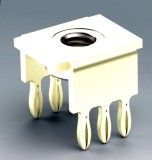

The wire-wrap technology according to DIN EN IEC 60352-1

The wire-wrap connection technique was introduced in Germany in 1973 by the Deutsche Bundespost (DBP) to make connections at the distribution board of NF amplifier stations and 2-MBit distribution boards. Using a special winding tool, the wires were cut to the correct length, stripped, and applied solder-free through a wire wrap on the connecting pin.

The control computers of the Apollo program (Apollo Guidance Computer) were manufactured using the wire-wrap connection technique, which was then encapsulated with epoxy resin.

The European Space Agency also regulated its use in its own standard (ECSS-Q-70-30A) entitled "Solderless electrical wire connections of high reliability."

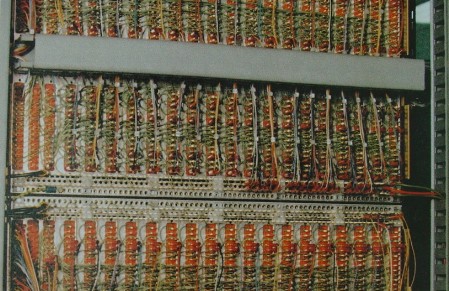

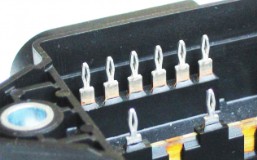

Wire-wrap techniques were also used in the backside wiring of the carrier board (backplane) of connectors for plug-in cards in appliances and early computers. For this purpose, the pins of the connectors protrude from the back of the carrier board and can be wired individually.

The wire-wrap technique is rarely used today. Multilayer and press-fit technology have replaced wire-wrap technology.