Metal plates, punched grids, lead frames

BIZON contacts contact metal plates, stamped grids, busbar, slip rings, leadframe.

The advantages and safety of press-fit technology are increasingly being used beyond the application of printed circuit boards.

Metallic elements must also be contacted. Miniaturization often does not provide direct access (soldering, welding) to the joint.

Press-fit technology is ideal for all these applications.

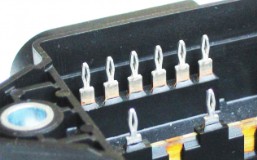

- Punched connecting elements (punched grids) have been used in the automotive industry for a long time. They are mostly made of brass. The BIZON contact can also be made of brass. There is no contact corrosion. Other material combinations are possible at any time.

- Compact electric motors use punched fasteners due to high currents (busbar).

- For battery management, secure connection taps must be made on the pole connectors for each cell.

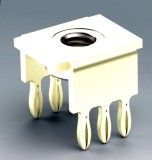

- Leadframes must be contacted. Press-fit technology does not require direct access to the connection point.

In order for the electrical connection of the other "base material" metal to function just as safely as with a printed circuit board, a number of things have to be observed.